Lightweight aluminum milling cutter

CAL CUTTER

Lightweight, high-strength aluminum body

low cost, and high performance

- Lightweight, high-hardness aluminum body front milling cutter

- Its original design physically prevents and suppresses spring-out of cartridges and inserts.

- Since only a small number of parts is needed, it is easy to assemble.

- Adjustable screws can easily suppress frontal deflection within 10 μm. High precision and long life.

- Unique installation direction by Chukyo’s original insert shape improved rigidity.

CAL cutter selection guide

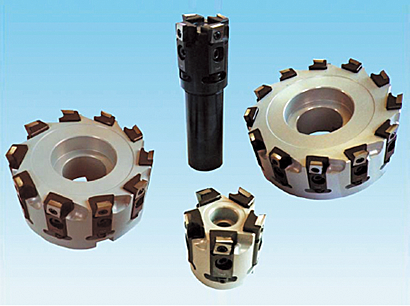

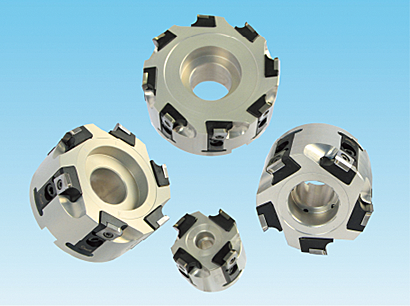

CAL-MAX/Plus

Super finer pitch + Internal coolant supply model

Characteristics

The product directly injects cutting oil to the cutting edge to improve lubricity and cooling effect, and it enhances suppression capacity of tool wear.

It pushes chips off and has higher chip discharge power.

It will improve machining accuracy and surface roughness of work materials.

CAL-F/Plus

Multi-bladed, internal oil supply type, for flat machining and corner cutting

Characteristics

- The product directly injects cutting oil to the cutting edge to improve lubricity and cooling effect, and it enhances suppression capacity of tool wear.

- It pushes chips off and has higher chip discharge power.

- It will improve machining accuracy and surface roughness of work materials.

CAL-F

Multi-bladed, for flat machining and corner cutting

Characteristics

- Lightweight, high-hardness aluminum body front milling cutter

- Its original design physically prevents and suppresses spring-out of cartridges and inserts.

- Since only a small number of parts is needed, it is easy to assemble.

- Adjustable screws can easily suppress frontal deflection within 10 μm. High precision and long life.

- Unique installation direction by Chukyo’s original insert shape improved rigidity.

CAL-S

Standard blade number, for flat machining

Characteristics

- A larger insert is used.

- Standard cutter with excellent rigidity.

- The cutting edge is hard to break even during gate processing (e.g. sprue, overflow) due to its unique shape.