PCD/PcBN Helical end mill

Eco - Helix

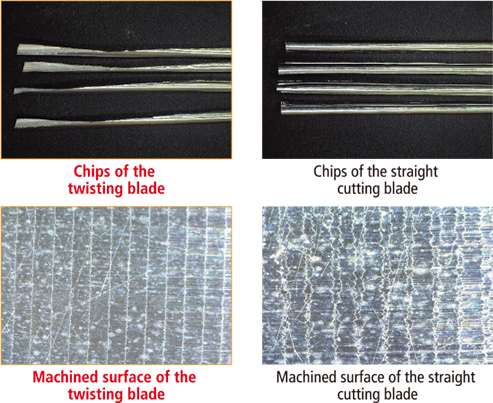

Because cutting resistance is reduced by the twisting blade effect, faster processing speed is possible.

The roughness of machined surface is greatly improved by the twisting blade effect.

- The cutting resistance of PCD/PcBN end mill is reduced because of the helical blade.

- Cutting performance of difficult-to-cut materials is dramatically improved!

Eco-Helix selection guide

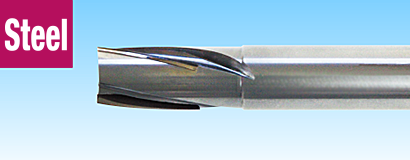

PcBN Eco-Helix

For hardened steel

Characteristics

- High-hardness hardened steel: Ideal for processing SKD 11 (60 HRC or more), SCR 15 (55 HRC or more) etc.!

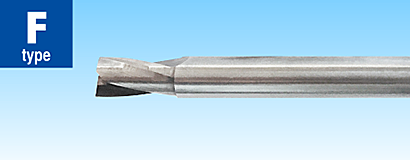

PCD Eco-Helix Trim Type F

For plastic and non-metal materials

Characteristics

- Ideal for trimming plastic and fiber reinforced plastic.

- 3-times faster processing speed than the straight blade type because of the spiral blade.

- Improved blade rigidity, reduced cutting heat, and suppresses burrs.

PCD Eco-Helix Type H

For plastic and non-metal materials

Characteristics

- Ideal for processing CFRP and hard resin!

- Spiral blade is adopted with 10 degrees twist.

- Improved cutting performance realizes enhanced machined surface accuracy and extended blade lives.

PCD Eco-Helix mini Type M

For non-metal materials

Characteristics

- Ideal for processing of MMC, duralumin, and nonferrous alloys!

- By the short-cut length design of conventional type M, inexpensive price setting is realized.

- High rake design realizes further reduction of cutting resistance.

PCD Eco-Helix Type M

For non-metal materials

Characteristics

- Ideal for processing of MMC, duralumin, and nonferrous alloys!